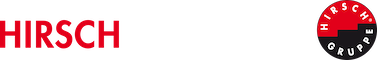

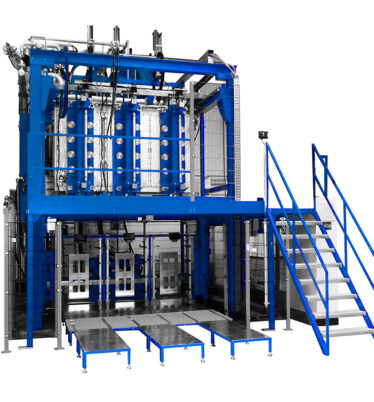

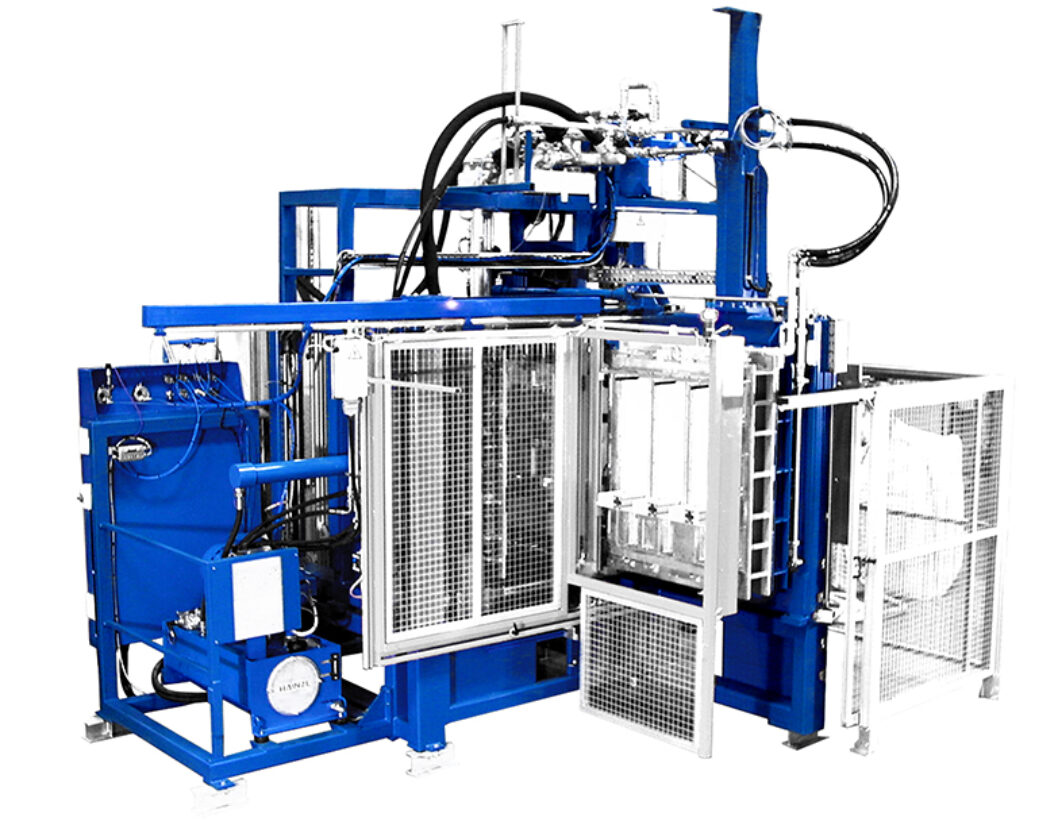

EPS Shape Molding Machines

We give shape to your products

Efficiency in production and operation

Shape molding machines for processing EPS, EPP and molded pulp

It is the years of experience in in-house processing, expertise in application, and the unique combination of mold making and mechanical engineering that have cemented the HIRSCH Maschinenbau shape-molding machines’ for processing EPS, EPP and molded pulp excellent reputation. Their precision steam consumption metering and the use of an insulated aluminum steam chamber enable the end products to be manufactured highly energy efficiently. As the technology leader in producing ICFs, HIRSCH guarantees particularly fast tool changes thanks to the package setup and an extremely high level of safety for the operators – not just in this area.